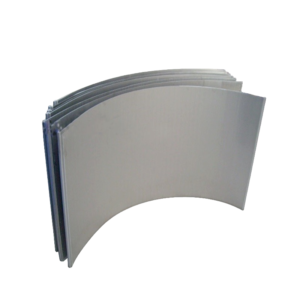

1. High-tension design

• Unique tensioning method: The tensioned screen plate applies tension to the screen plate during installation to ensure that the screen plate does not loosen or deform during operation. This high-tension design can effectively improve the stability and durability of the screen plate, especially in long-term vibration and high-load working environments.

• Excellent screening stability: Due to the special design of the tensioning structure, the screen plate can maintain high screening accuracy and efficiency even under high-intensity vibration, reducing the bending and damage of the screen plate.

2. Strong wear resistance

• Extremely high wear resistance: The tension screen plate is made of high-quality steel or high-alloy steel, which has strong wear resistance, especially when screening hard minerals and coarse particles, which can effectively extend the service life. This wear resistance is one of its unique characteristics, especially suitable for screening highly abrasive materials such as stone and ore.

3. High load-bearing capacity

• Strong load-bearing capacity: Through special structural design and high-quality materials, the tension screen plate can withstand large loads and is suitable for high-load and high-intensity screening operations. It is especially suitable for large-scale vibrating screening equipment that requires long-term high-intensity work.

4. Wide application

• Applicable in multiple scenarios: The relaxation screen plate is not only suitable for screening highly abrasive materials such as ore, coal, sand and gravel, but also performs well in screening wet and sticky materials in industries such as chemical, metallurgy and construction. Its diverse application scenarios make it an indispensable screening material in many industries.

5. High temperature resistance and corrosion resistance

• Special materials adapt to high temperature environment: Some loose screen plates use high temperature resistant materials to adapt to high temperature working environment (such as ore screening, high temperature coal screening, etc.). In addition, some loose screen plates made of high alloy steel or stainless steel can withstand the screening of corrosive materials, such as acid and alkaline material screening in the chemical industry, and have excellent corrosion resistance.

6. Low material clogging rate

• Precision aperture design: The aperture design of the loose screen plate can be customized according to the particle size requirements of the material to ensure that the material will not be blocked when passing through the screen plate. Especially for wet and sticky materials, the special design of the loose screen plate can effectively avoid material blockage and improve screening efficiency.

Flip-flow screen plate

The tensioned screen plate has the advantages of high strength, strong wear resistance, good impact resistance, and corrosion resistance, and is widely used in material screening in mining, metallurgy, chemical industry, building materials and other industries. It is installed in a tensioning manner to maintain a stable screening effect, and is suitable for screening operations in high-load and harsh environments.

Additional information

| parameter | 1. Strong shock absorption effect |

|---|

Reviews

There are no reviews yet.