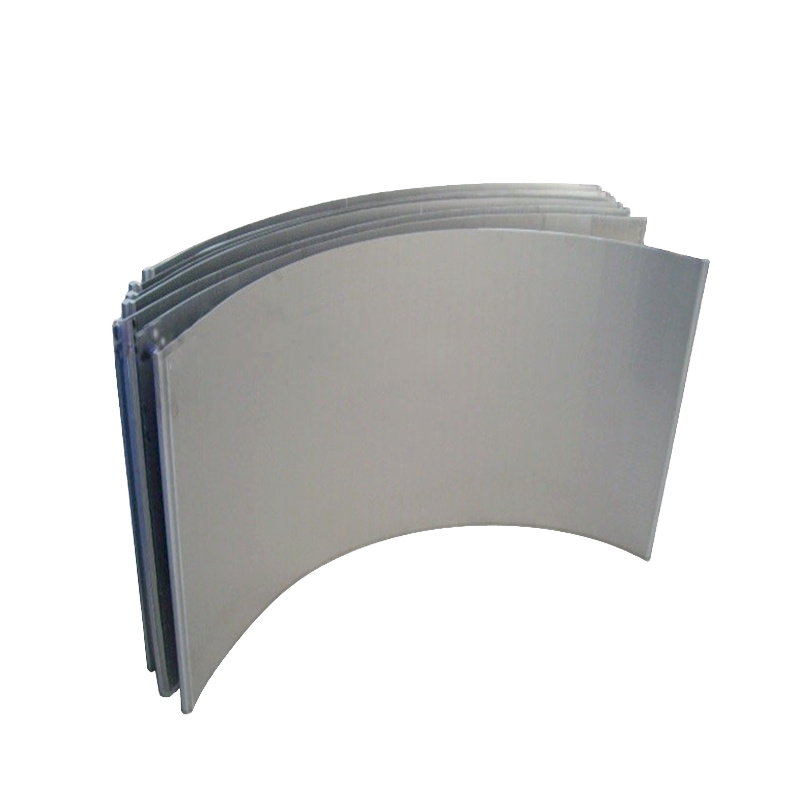

The super-efficient curved screen is a high-efficiency equipment optimized for wet screening and dehydration. It adopts a curved screen surface design (adjustable inclination of 30°~60°), combined with wear-resistant polyurethane or stainless steel screen plates (adjustable screen slots of 0.1~3mm), and realizes non-powered screening through material gravity and centrifugal force. The processing capacity reaches 10~500 tons/hour, the screening efficiency is ≥90%, and the moisture content after dehydration is ≤15%. Its inverted trapezoidal screen slot structure has a self-cleaning function, which significantly reduces the risk of clogging. The polyurethane screen plate has a lifespan of up to 6~12 months, and its wear resistance is 2~3 times that of traditional metal screens. The modular design supports rapid replacement of screen plates, with extremely low maintenance costs. It is suitable for coal washing (coal slime dehydration), mine slurry classification, sand and gravel aggregate fine powder separation, and sewage treatment. The equipment runs without a vibration motor, the noise is ≤70dB, and the closed structure prevents leakage, which meets environmental protection requirements. With high efficiency, low consumption, and long life as its core advantages, it is an ideal solution for screening and dehydration of wet fine particles.

High efficiency curved screen

The super-efficient curved screen is a highly efficient static screening equipment designed for wet screening, dehydration and fine particle classification. Through the unique curved screen surface and non-powered operation mode, it can achieve rapid separation and dehydration of high-water-content, fine-particle materials (such as ore pulp, coal slime, sand and gravel aggregates, etc.). Its core design integrates the principles of fluid mechanics and wear-resistant material technology. With high-efficiency screening, low energy consumption and long life as its core advantages, it is widely used in coal washing, mine dressing, building materials processing and environmental sewage treatment.

Additional information

| parameter | Curved screen surface: adopts curved surface design (radius 0.5~2m), uses material gravity and centrifugal force to accelerate screening, and the screen surface inclination angle is adjustable (30°~60°). |

|---|

Reviews

There are no reviews yet.