Main structure

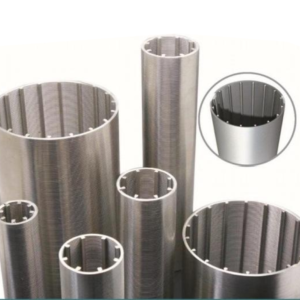

Drum (screen basket):

Core separation component, made of high-strength wear-resistant material (such as high-chromium cast iron, tungsten carbide coating or ceramic lining), with slits or round hole screens designed on the inner wall (adjustable aperture 0.05~1mm), responsible for intercepting solid particles and discharging liquid under the action of centrifugal force.

Screw conveyor:

It is coaxial with the drum but has a speed difference (differential speed 0.5~30r/min). The spiral blades push the deposited solids to the slag discharge port to achieve continuous slag discharge.

Drive system:

Dual motor drive (main motor drives the drum, auxiliary motor adjusts the differential speed) or hydraulic drive, equipped with frequency converter to achieve precise speed control (drum speed 500~4000r/min).

Casing and shock-absorbing system:

The closed design prevents material splashing, and the shock-absorbing base reduces operating noise and vibration.

Working Principle

The ore pulp enters the high-speed rotating drum through the feed pipe. The solid particles with higher density are quickly deposited on the inner wall of the drum under the action of centrifugal force to form a filter cake; the liquid (filtrate) is discharged through the sieve holes. The screw conveyor rotates at a speed slightly lower than that of the drum, pushing the solid filter cake to the slag discharge end to achieve continuous solid-liquid separation. By adjusting the speed, differential speed and mesh aperture, the moisture content of the separated solid (as low as 10%~15%) and the particle classification accuracy can be controlled.

Reviews

There are no reviews yet.