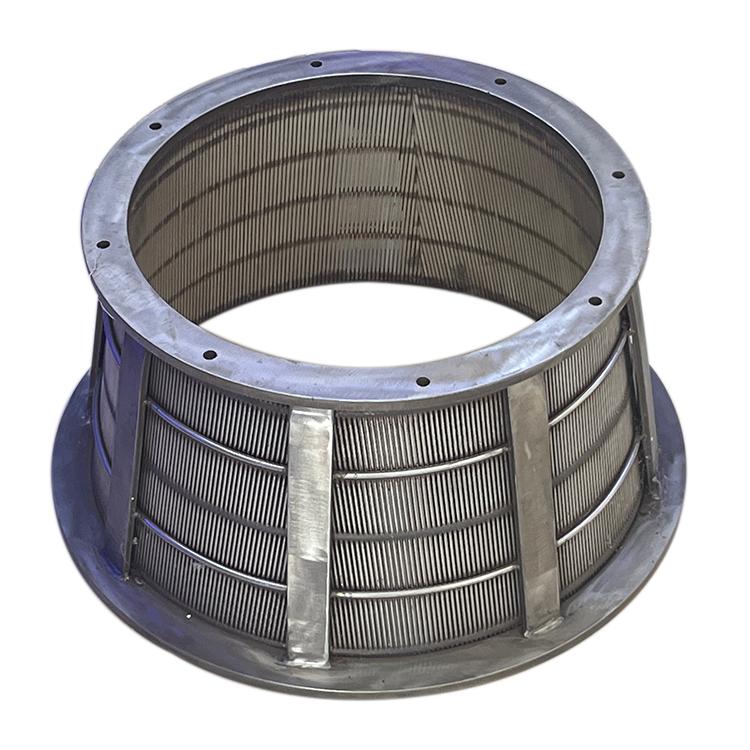

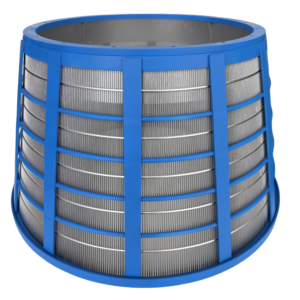

Screen basket introduction

Screen basket is the core component of centrifugal separation, vibration screening and other equipment, mainly used for solid-liquid separation, particle classification or material dehydration.

Structure and material

Screen surface: Stainless steel (304/316L) or polyurethane, with various opening forms (slits, round holes, diamond holes, etc.), aperture range 0.1-10mm, high precision.

Frame: Stainless steel or carbon steel support structure, enhances overall strength, adapts to high-speed rotation or vibration conditions.

Connection method: Modular design, can be assembled or welded, suitable for centrifuges, vibrating screens and other equipment.

Core features

Efficient separation: precise mesh design improves solid-liquid separation efficiency and reduces material residue.

Wear-resistant and corrosion-resistant: stainless steel is corrosion-resistant, polyurethane is impact-resistant, and can adapt to high wear and acid-base environments.

Strong stability: rigid frame + elastic screen surface combination reduces deformation risk and prolongs service life.

Easy maintenance: supports partial replacement of screens to reduce downtime costs.

Application areas

Mining: tailings dehydration, mineral classification.

Environmental protection: sludge dehydration, sewage treatment.

Food and chemical industry: screening and drying of sugar, salt, and crystalline materials.

Pharmaceuticals: fine powder classification, liquid drug filtration.

Advantages: It combines strength and precision, is suitable for high-speed and high-load conditions, and is an efficient solution for industrial separation and screening.

Reviews

There are no reviews yet.