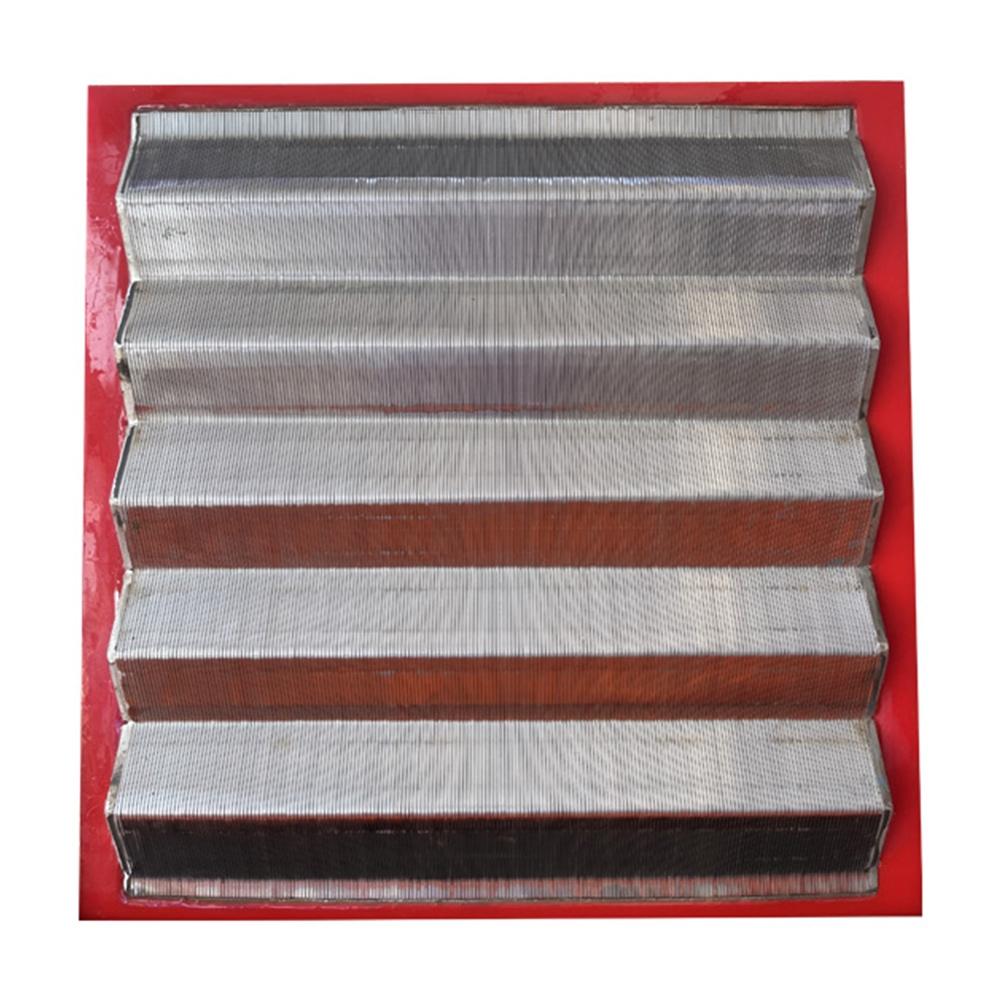

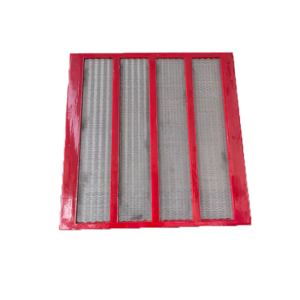

Polyurethane frame stainless steel slotted sieve plate introduction Polyurethane frame stainless steel slotted sieve plate is a widely used equipment for screening and filtering, combining the advantages of polyurethane and stainless steel, suitable for a variety of industrial fields.

1. Structure

Stainless steel slit screen bars: Made of high-quality stainless steel, with high strength and corrosion resistance, the screen bar gap is uniform and the screening accuracy is high.

Polyurethane frame: The frame is made of polyurethane material, which has good elasticity, wear resistance and impact resistance, and can effectively reduce the wear of the screen plate and equipment and extend the service life.

2. Features

High wear resistance: The polyurethane frame and stainless steel screen bars have excellent wear resistance and are suitable for handling highly abrasive materials.

Corrosion resistance: Stainless steel can resist corrosion from a variety of chemicals and is suitable for humid and corrosive environments.

Good elasticity: The elasticity of the polyurethane frame can reduce material impact, reduce noise, and improve screening efficiency.

High screening accuracy: The gap between the stainless steel bars is uniform, ensuring high-precision screening effects.

Easy installation and maintenance: Reasonable design, easy installation and replacement, and reduced downtime.

3. Application fields

Mining: used for screening of ore, coal, etc.

Sewage treatment: used for solid-liquid separation and filtering solid particles in sewage.

Food processing: used for screening and filtering food raw materials.

Chemical industry: used for screening and filtering of chemical raw materials.

4. Advantages

Long life: The combination of polyurethane and stainless steel prolongs the service life of the screen plate.

Efficient screening: The uniform slit design improves screening efficiency and accuracy.

Economical: Reduce maintenance and replacement frequency, and reduce operating costs.

Summary

Polyurethane frame stainless steel slotted screen plates are widely used in many industries due to their wear resistance, corrosion resistance, high-precision screening and other characteristics. They are ideal for screening and filtering.

Reviews

There are no reviews yet.