Features:

1. Shock and noise reduction

The rubber material itself has good elasticity and shock absorption performance. During the operation of the vibrating screen, it can effectively reduce noise and reduce the impact of vibration on the equipment, thereby increasing the service life of the equipment.

2. Flexibility and elasticity

The rubber screen plate has good elasticity and can adapt to the screening needs of different materials, especially for the screening of wet and sticky materials. It can effectively prevent material blockage and improve screening efficiency.

3. Easy installation and maintenance

The rubber screen plate is light in weight, simple to install, and can be customized as needed. Due to its softness, it is more convenient and quicker to disassemble, clean and replace than the metal screen plate.

4. Widely used

Rubber screens are widely used in material screening and grading in mining, coal, electricity, fertilizer, building materials and other industries, especially for screening of coarse particles and wet materials such as stone, coal, ore, etc.

Typical applications: screening and grading of mining materials, screening of sand, gravel, coal and other materials, grading of chemical raw materials, fertilizers and soil, and processing of materials with high water content or viscosity.

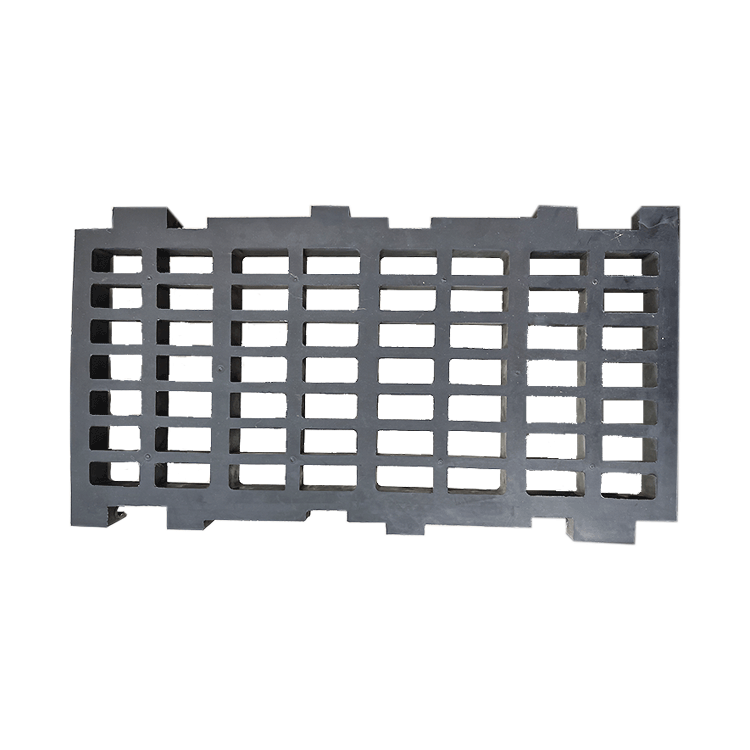

Rubber screen plate

Rubber sieve plate is a sieve plate used in vibrating screening equipment, mainly used for material screening and grading in mining, chemical, building materials, metallurgy and other industries.

Additional information

| parameter | 1. High tensile strength |

|---|

Reviews

There are no reviews yet.